ELECTRICAL AUTOMATION

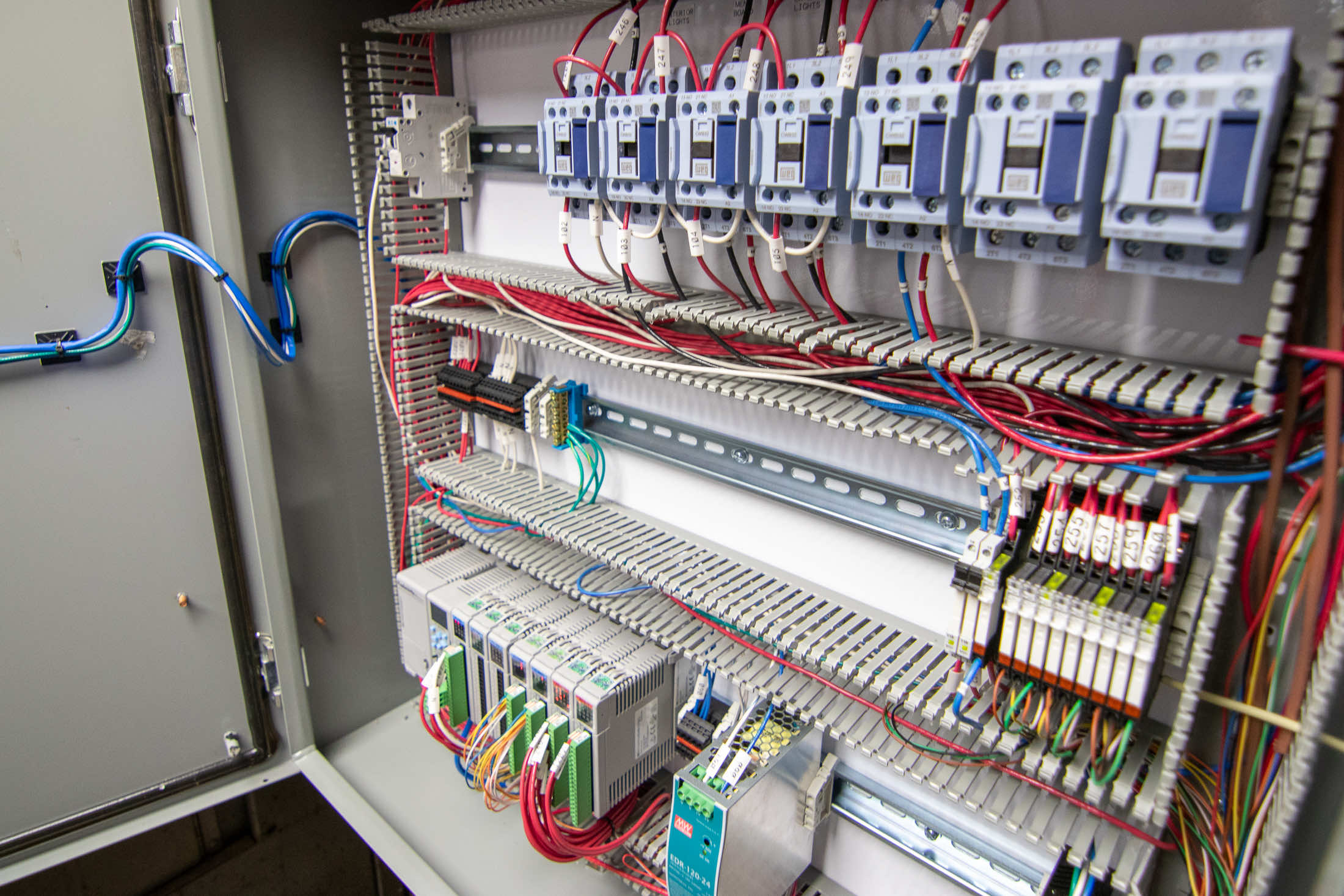

Design & Fabrication of Control Systems

The automation design process ensures that control systems are meticulously designed, built, and maintained to meet specific operational goals while adhering to safety and performance standards. This process helps reduce production costs and labor, ensuring consistent operation and ultimately providing a significant dividend to your bottom line. By optimizing efficiency and reliability, automation design play a crucial role in enhancing overall productivity and profitability.

Our Solution

Conducting an assessment to identify operational goals and requirements is the first step in designing and implementing a system tailored to your needs. High-quality components to match the design specifications are used and rigorous testing will verify the system is effective and reliable.

Process Automation Controls

Process Automation controls are essential for optimizing commercial and industrial processes, ensuring consistency, efficiency and safety. By leveraging these components and benefits, businesses can ensure their processes are robust, efficient, and safe.

Our Solution

Assess and integrate system components, such as sensors, controllers, actuators, or software to best meet operational goals.

Energy Demand Controls

Energy controls are essential for reducing peak spikes during equipment startup and operation, which in turn helps lower energy costs. By managing these spikes, energy controls contribute to a more consistent and efficient system for running your production facility. This not only enhances operational stability but also supports cost savings and improved overall performance.

Our Solution

Designing and implementing solutions like programmable control logic not only reduces operational cost but also support a more sustainable and efficient energy system. As an approved participating contractor for the Dominion Energy Commercial Lighting Systems and Controls program, we can explore various cost-saving initiatives and determine eligibility qualifications. This program offers attractive rebates for upgrading existing lighting or installing new energy-efficient lighting and controls, which can significantly enhance energy savings and improve the overall efficiency of your facility.

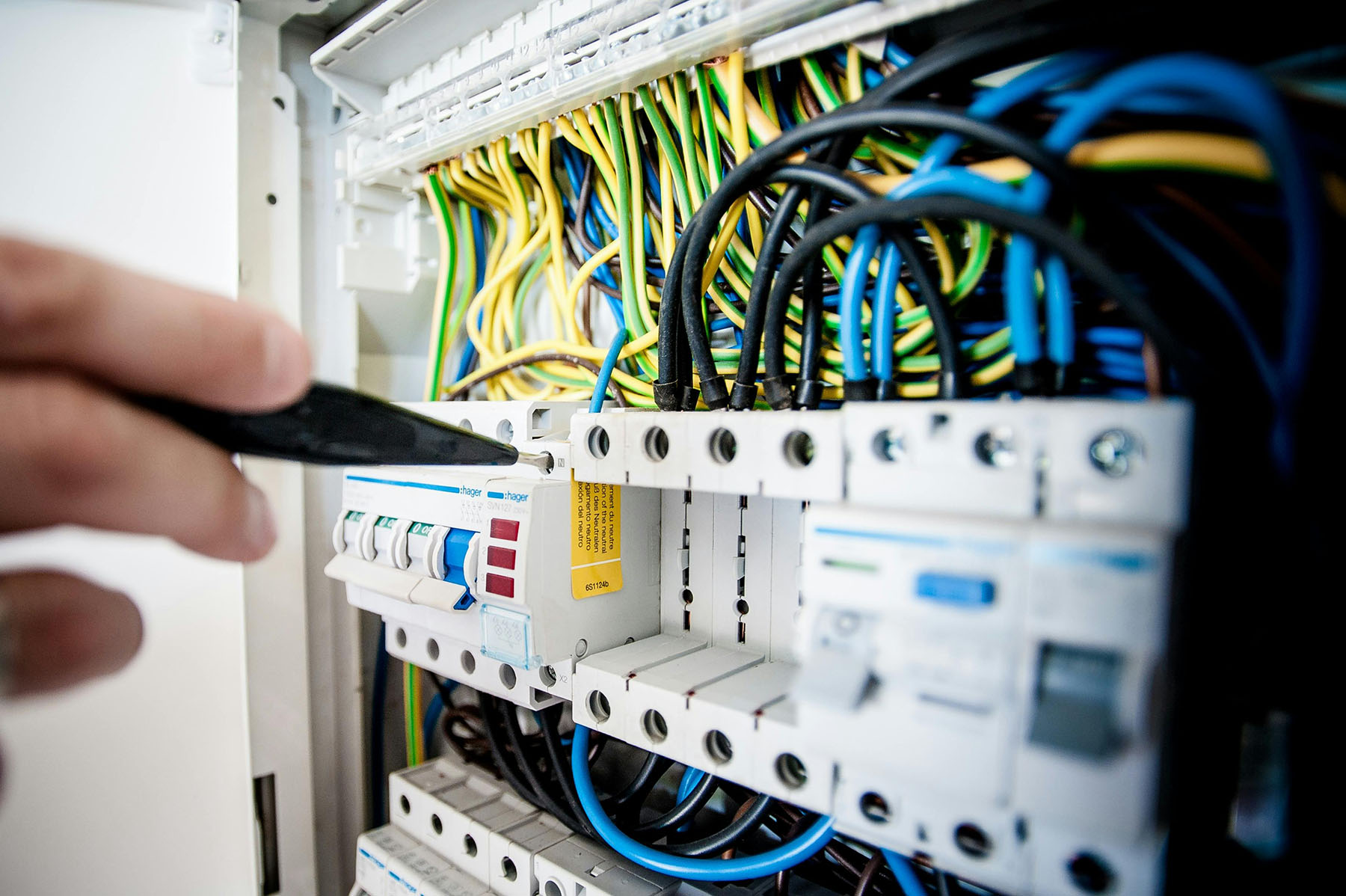

Troubleshooting & Repairs Electrical Automation

Troubleshooting and repairing electrical automation systems involves identifying, diagnosing, and fixing issues within automated machinery and control systems.

Our Solution

Predictive and preventive maintenance are key strategies in maintaining the reliability, efficiency of equipment and controls. They identify potential issues before they cause significant downtime, ensuring smoother operations and longer-lasting equipment.